Comparison of Microwave and Conduction Heating for Solid Phase Peptide Synthesis

In collaboration with University of California, Davis; UCD evaluated microwave and conduction heating and presented the findings at the 28th American Peptide Symposium.

In this case study, we evaluate the effect of temperature on the speed of synthesis and crude purity

When performing solid phase peptide synthesis there are multiple factors that contribute to the quality of the produced peptide, the speed of the synthesis, and solvent consumption. A few factors include the coupling chemistry, the amount of time for deprotection and coupling phases as well as the temperature of the synthesis environment. A common question researchers ask when inquiring about automated peptide synthesizers is: “What can I expect my crude purity to be?” and “How long will it take to make a peptide?”

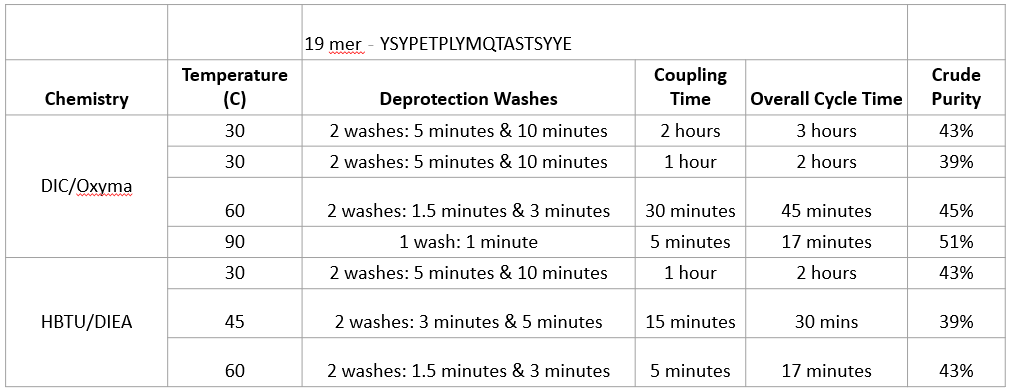

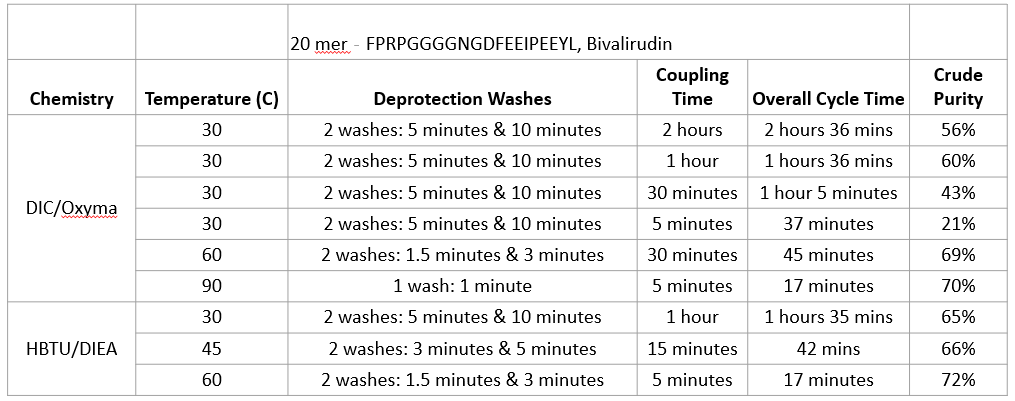

In this case study, we break down how the two most common chemistries used for SPPS at different temperatures and deprotection and coupling durations affect peptide crude purity.

Solid phase peptide synthesis requires a series of steps for each amino acid to build the peptide chain: Deprotection, washing, coupling, washing, repeat. At CSBio we synthesized two peptides with both DIC and HBTU chemistry with different temperatures and cycles times, and evaluated the effect on crude purity.

All peptides were synthesized on Rink amide resin at a 0.2 mmol scale on a CSBio II Peptide Synthesizer. The temperature was set on the CSBio II Peptide Synthesizer, maintaining the temperature of both the reaction vessel as well as the pre-solvent delivery (both the wash solvent and deprotection solution are preheated prior to delivery to the reaction vessel) at the temperature noted in the table.

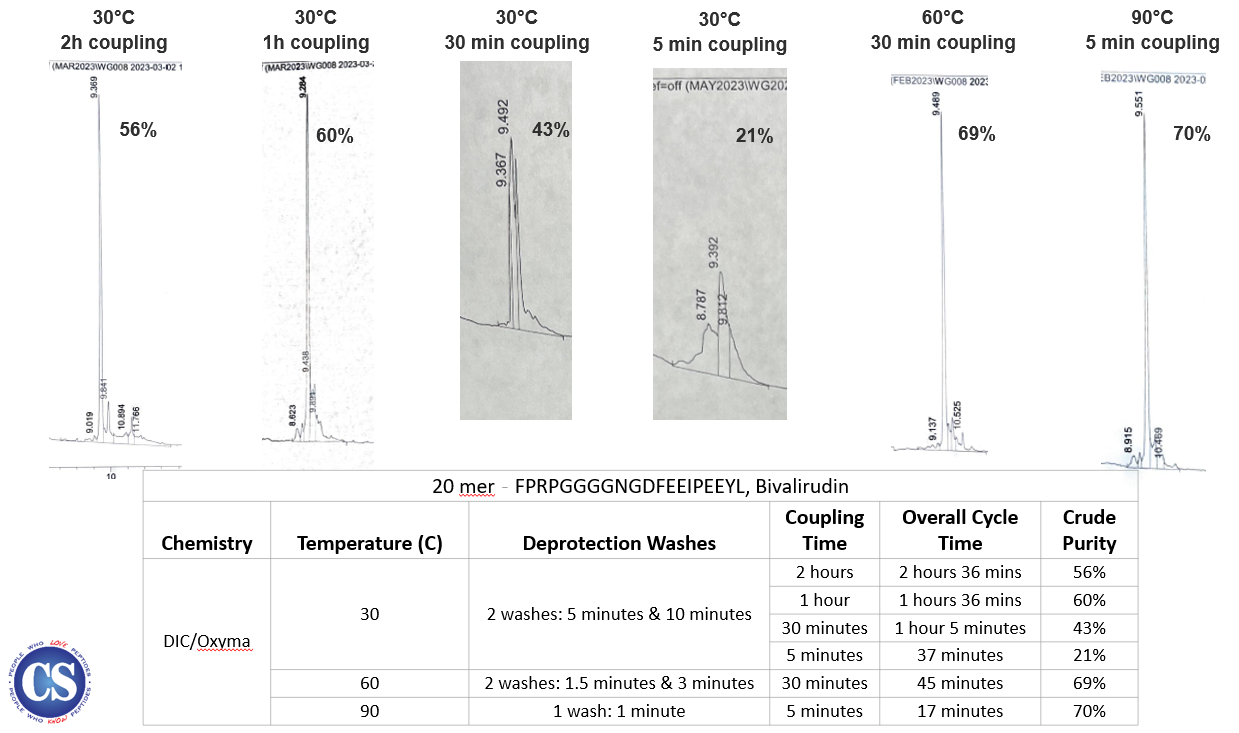

From the data, we can see that by increasing the temperature, we are able to reduce the coupling time to maintain or even produce higher crude purity. Additionally, if we maintain the same temperature for the synthesis while decreasing the coupling time, as expected it will significantly negatively impact the crude purity. As evident more clearly as organized and shown below with the crude purity peaks.

Increasing the synthesis temperature is the best way to optimize the overall cycle time, allowing users to shorten the deprotection and coupling phases of synthesis, regardless of the chemistry or individual peptide sequence.

About CSBio: For over 30 years, CSBio, a leading peptide and peptide synthesizer manufacturing company located in Silicon Valley, California, has been providing cGMP peptides and automated peptide synthesizers to the global pharmaceutical community. CSBio’s peptide products and peptide synthesizers can be found in production laboratories, universities, and pharmaceutical companies worldwide.

Interested in any of our peptide synthesizers? Get in touch with us.

In collaboration with University of California, Davis; UCD evaluated microwave and conduction heating and presented the findings at the 28th American Peptide Symposium.

Synthesis of peptides at any length requires extreme attention to detail for accuracy and purity of the desired compound...

The latest peptide research around the world focused on defeating coronavirus.

CSBio is a leading peptide and instrumentation manufacturing company located in Silicon Valley, California.

CSBio provides nonGMP and cGMP peptides, peptide APIs, research scale peptide synthesizers, commerical scale peptide synthesizers, DNA/RNA oligonucleotide synthesizers, and preparative HPLC purification equipment.

915 Linda Vista Ave

Mountain View, CA, 94043

+1-650-525-6200